Why Polymer Components are Crucial in EV Manufacturing

The rise of electric vehicles has done more than just redefine the powertrain, it’s revolutionised the way manufacturers approach material selection and product design. Today, polymer components in electric vehicles are doing much more than filling in the gaps. They’re making EVs lighter, safer, more efficient and easier to build.

From interiors and battery management systems to body structures, polymers in electric vehicle manufacturing are solving problems that metals can’t, all while helping brands achieve performance, cost and sustainability goals.

Here’s how polymers are helping shape EV manufacturing:

Table of Contents

1. Reducing Weight Without Sacrificing Strength

Weight matters more in EVs than in conventional vehicles. Batteries are heavy so cutting weight elsewhere is one of the best ways to improve range. That’s why manufacturers are increasingly turning to lightweight materials for electric vehicles, especially polymers and composites.

These materials are much lighter than steel or aluminium, yet strong enough for many structural and functional parts. Less weight means better acceleration, lower energy use and improved driving range.

Many EV makers are now using fibre-reinforced polymers for battery mounts, brackets and even entire front-end modules.

2. Managing Heat and Electricity with Confidence

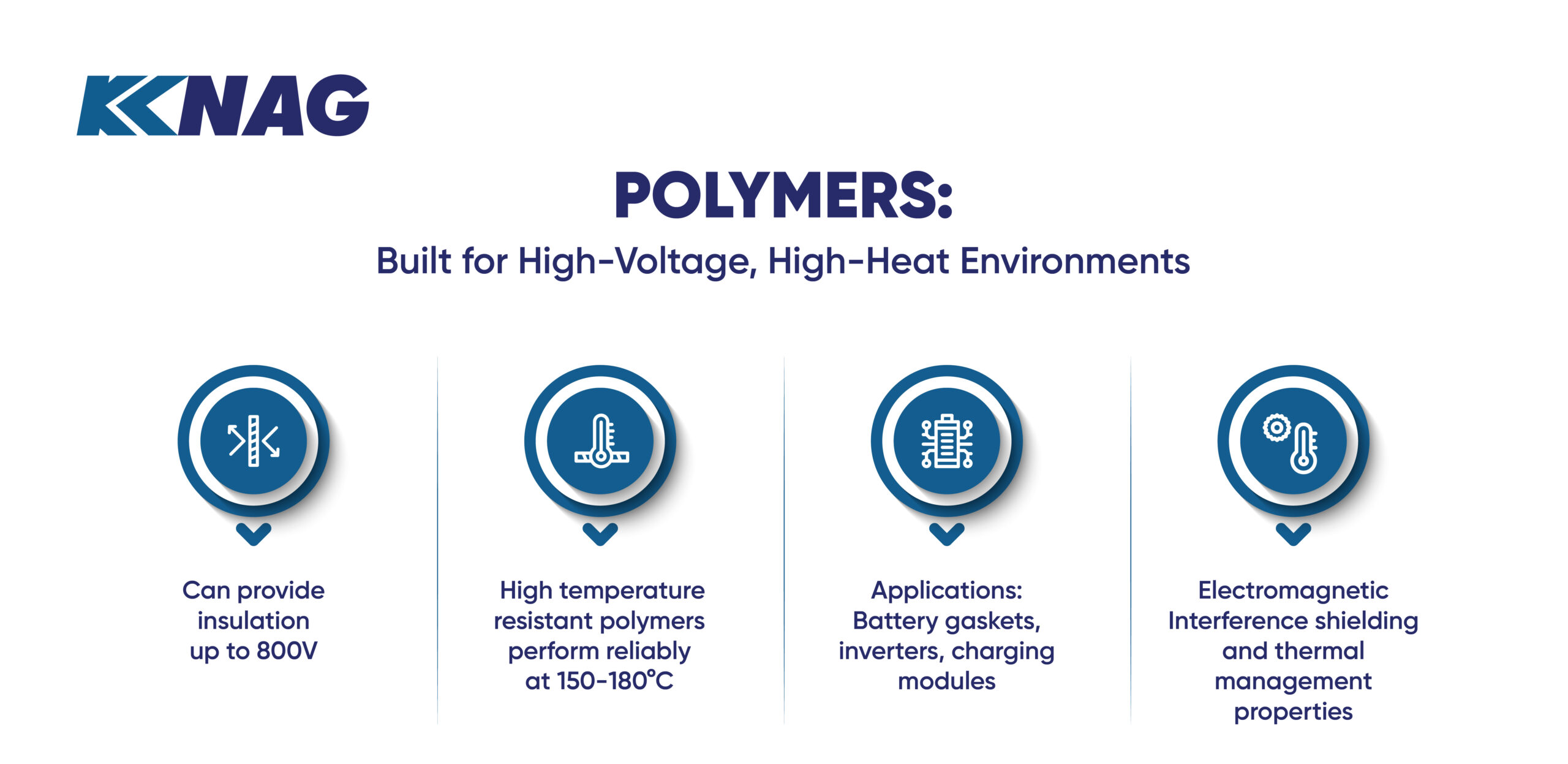

Electric vehicles generate a lot of heat and rely on high-voltage electrical systems. Managing both safely is critical. Fortunately, polymers in electric vehicle manufacturing have some natural advantages here.

They insulate electricity by default, helping prevent short circuits or electrical failures. Many thermoplastics can withstand high temperatures, making them ideal for use around batteries, inverters and power electronics.

3. Improving Structural Support and Safety

Polymers aren’t just for trim parts or wiring covers. New-generation polymer blends and composites are used to handle real structural demands.

You’ll now find these materials in crash zones, support beams and underbody shields. They resist corrosion, absorb energy in collisions and hold up well under stress.

In fact, several automakers use polymers to create front crash beams and battery tray supports that protect passengers during impact. These materials help reduce injury risks while cutting down on weight.

4. Helping Designers Do More with Less

One of the biggest perks of polymer components in electric vehicles is how they simplify the design process. Polymers are easy to mould into complex shapes so parts that would usually need to be assembled from multiple components can often be created as one piece.

This opens the door to more integrated, space-saving designs. Whether it’s a dashboard that also provides thermal insulation or a battery casing with built-in wiring channels, polymers let engineers get creative.

As a bonus, fewer parts means faster assembly and lesser concerns about what can go wrong in production.

5. Making EVs Scalable and Affordable

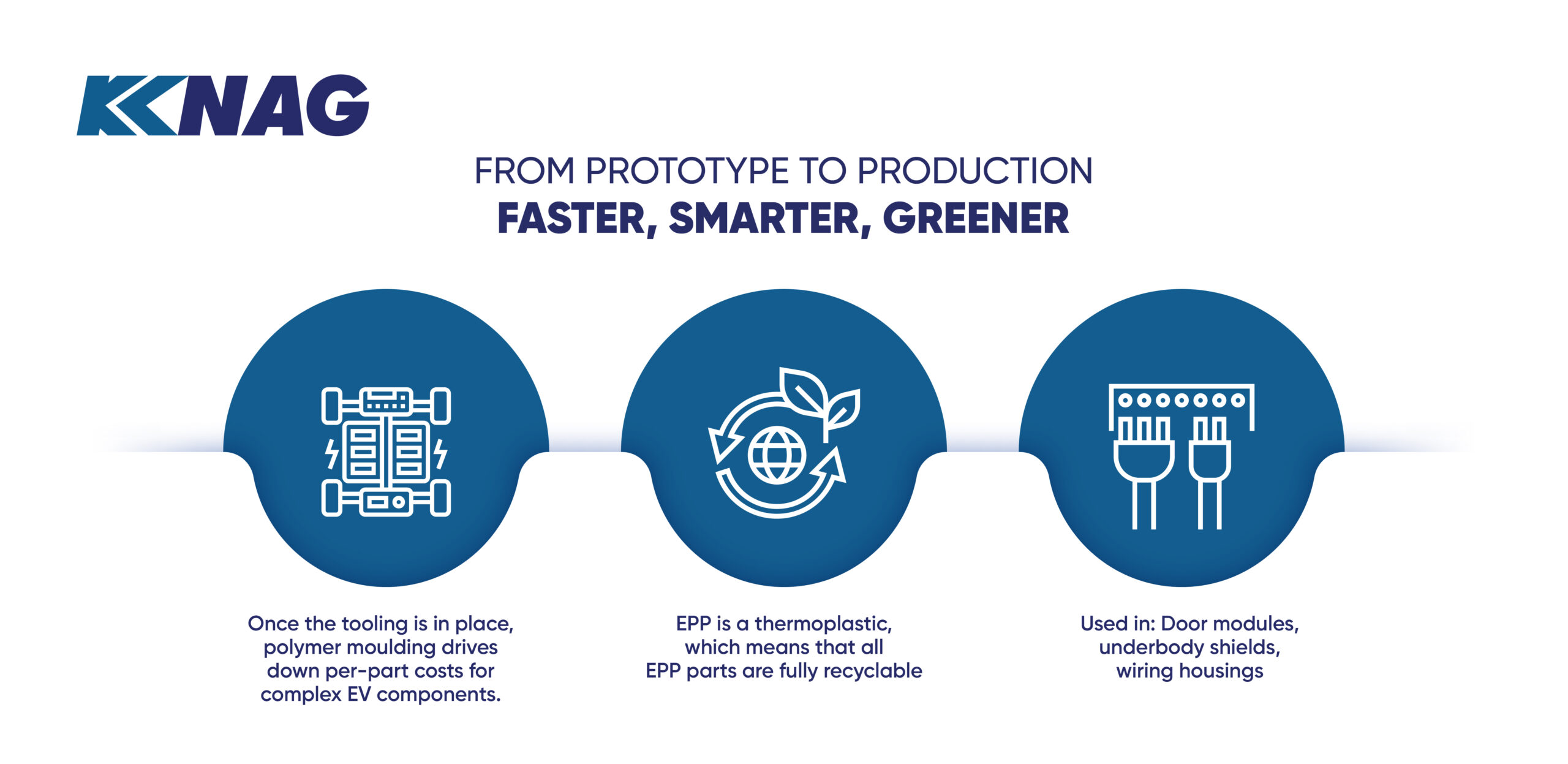

Polymers are quicker to mould than metals, especially for high-volume production. Tools cost less, cycle times are shorter and many polymer parts can be made using local resources. Some can even be 3D printed.

Plus, since thermoplastics are recyclable, manufacturers can reduce waste and move toward more circular production models.

Conclusion

Whether you’re building a compact urban EV or a long-range SUV, the materials you choose can make or break performance. Today, polymer components in electric vehicles are providing far more than just support. They’re shaping the future of how EVs are designed, built and experienced.

Polymers bring together low weight, strong performance, design flexibility and production efficiency—qualities that help brands move faster, scale smarter and drive more sustainably. With proven expertise in advanced polymer foams and moulded solutions, K. K. Nag helps make these advantages real for EV manufacturers.

As electric mobility surges ahead, advanced polymer foams and moulded polymer solutions will continue to support lighter builds, safer batteries and uncompromising efficiency.